Large Micro Brewhouse

Size: 20-100hl (20-100bbl)

Vessel: 3, 4 or more vessels

Heating: Steam or Gas

Design: CAD or 3D designs are provided

**STANDARD FEATURES**

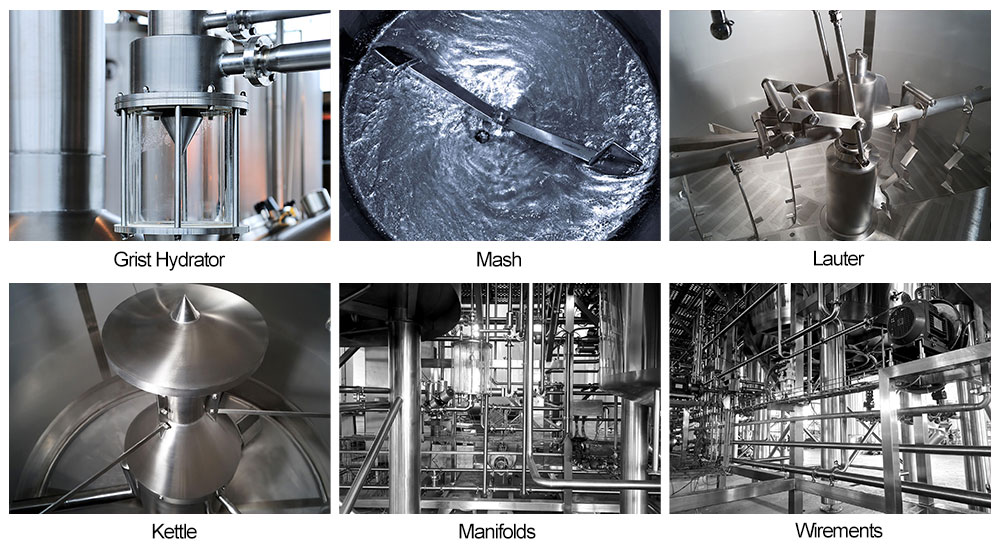

• 1 x Brew kettle / whirlpool vessel with multi steam jackets

• 1 x Mash / lauter tun vessel with side and bottom grain out doors, lauter rakes and grain out with variable speed control

• 1x Separate Mash tun with Mash Mixer and pump

• 1 x DOUBLE brew length HLT with dual steam jackets

• 1 x DOUBLE brew length cold liquor tank with dual glycol jackets

• 1 x work platform with sanitary process piping & sanitary valves

• 2 x Sanitary wort pumps with variable speed control

• 1 x HLT pump with variable speed control

• 1 x CLT pump with variable speed control

• 1 x Stainless wort grant

• 1 x Sanitary 2 stage heat exchanger and wort aeration system

• 2 x Water flow meter

• 1 x Nema 4X control panel

• 3 x Tank light assemblies

• 1 x Mash hydration assembly

• 1 x SS grist hopper

• 1 x grain auger

• 1 x CAD layouts and 3D design, installation assistance, assembly

• 1 x Add Sink & Flash Chiller

**OPTIONS**

• Separate whirlpool vessel and pump

• Internal & external calandria

• Extra capacity mash lauter tun

• Hopback

• Touch screen programmable logic controller (PLC) controls with Pneumatic valves

• Platform Modifications for Future Vessels

**Quality Assurance in Brewing**

At XG Machinery, we take pride in delivering top-tier solutions tailored specifically for the brewing industry. Our experienced sales and customer support teams are dedicated to ensuring that every brewery project not only meets but exceeds your expectations while aligning with your unique brewing requirements. We understand the significance of budgets and production timelines in the brewing sector, and we are committed to delivering results that matter.

Recognizing the individuality of each brewery, we engage in thorough consultations with our clients during the equipment procurement process. This collaborative approach helps us determine the ideal size, configuration, and fittings for your new brewing equipment. Following installation, our team works closely with yours to commission the brewing equipment, ensuring a seamless production process that consistently delivers the desired taste and yield with every batch.

**Internationally Recognized Quality Certifications**

We have implemented an efficient ERP management system and successfully passed rigorous quality audits to attain internationally recognized certifications highly esteemed in the brewing industry.

**Technical Support**

XG Machinery offers ongoing support for all our equipment. You can rely on us to provide information and assistance for your brewing processes. You can access resources on our website or contact us at any time for support, questions, or feedback. We warmly welcome your inquiries.

**On-Time and On-Budget Delivery**

We understand that acquiring new brewing equipment can be a significant investment and a complex process. At XG Machinery, our commitment to excellence extends beyond manufacturing. We take great pride in our ability to deliver equipment punctually and within the designated budget. Our dedicated project management team maintains regular communication with you, providing weekly updates on your project's status, complete with actual images of your equipment in the manufacturing pipeline. XG is a trusted name in the world of brewing.

INQUIRY

Categories

Reference

Contact Us

Contact: Marco Zhu

Phone: 86-15267853358

E-mail: sales@xgmachinery.com

Whatsapp:86-15267853358

Add: No.1 Xiyuan Industrial Park Xizhou Town, Xiangshan Ningbo, China 315721